Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

HAIXING rolling shutter strip making machine is Easy to operate: Modern molding machines are usually equipped with PLC control systems, with friendly operation interfaces, easy to learn and operate.

Save manpower: The high degree of automation reduces the dependence on operators and saves human resources.

Strong adaptability: Rolling shutter doors of various specifications and types can be produced to meet the needs of different customers and markets.

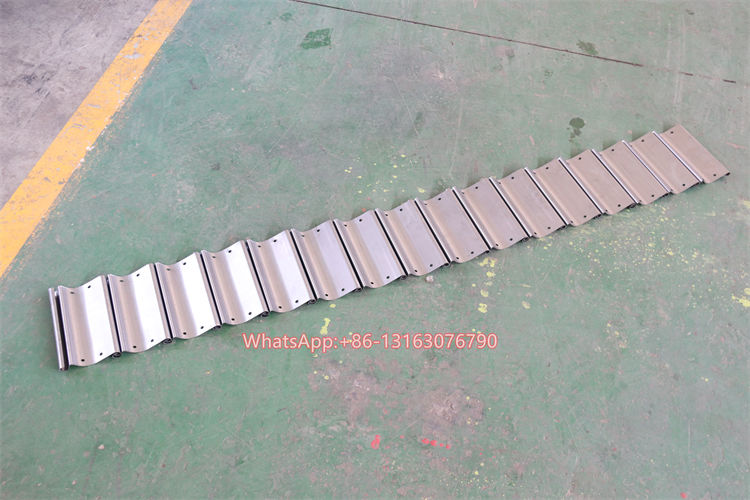

| Raw material | GI GL PPGI PPGL |

| Thickness | standard 0.4-1 or other thickness as you need |

| Machine size | around 5.8*0.7 *1.5m |

| Machine weight | around 3ton |

| Rollers | around 14 rollers, it depends on the profile drawing, CR12 Steel |

| Cut | Hydraulic cut |

| Maine motor | 4kw |

| Pump motot | 4kw |

| Shaft diameter | 70mm |

| Transmission | Chain |

| Control systerm | PLC control |

| Speed | 15m/min |

| Out put table | 3 meter, manual / Pneumatic to choose |

| Structure | Arch structure |

It include decoiler machine 3Ton, feeding, roll forming machine, PLC control, Touch screen, Hydraulic cut, output table 3 meters.

Rolling shutter door forming machines are provided with a warranty period of 2 years. Warranty for core components is provided. In addition, on-site maintenance and repair services, video technical support, online support and free accessories are also provided.

Our customers